Your cart is currently empty!

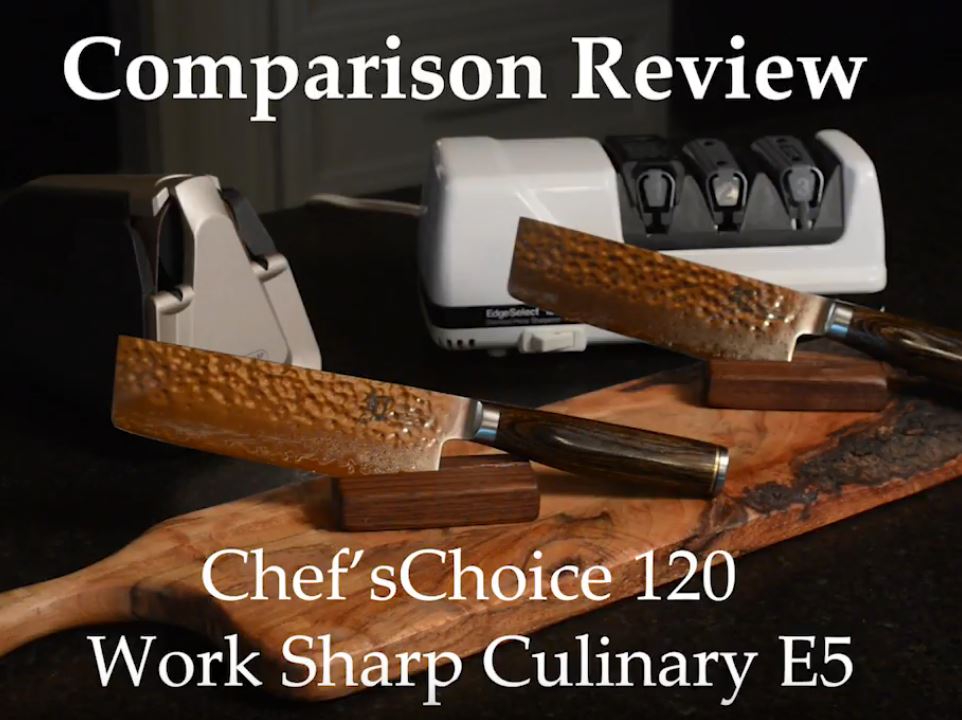

Work Sharp Culinary E5 Kitchen Knife Sharpener versus ChefsChoice 120

Here’s a video and write up from John Horwitz, and early adopter to the Work Sharp Culinary bandwagon comparing his experience with the E5 to the ChefsChoice 120 he was happy, but not in love with.

E5 v CC120: Some memories of early singledom are funny in retrospect. Cooking and the subsequent aspect of eating what had been cooked are not among them. My first apartment was advertised as “Room & Board” but the landlady had no idea what the word ‘Board’ actually meant. I had a hot plate, a dorm sized refrigerator, one thin, bent aluminum pot, a 5 oz. coffee mug and three pieces of stamped flatware labeled Horn & Hardart. The latter were an odd sized spoon, a knife and a four tined fork that was missing the leftmost tine.

Hotplates do one thing and do that one thing very well; they get hot. Unfortunately, this is a recipe for disaster as they have only ON or OFF and a really short time between stone cold and the red blisteringly Hellish fire that makes them famous. Searing meat was easy enough, it was the nuanced chores that required patience and skills. Lacking that necessary finesse, meals were either overly charred or lukewarm at best.

It was in those long ago and faraway days that I was given the present of my first great carbon steel knife. Rather than trying to saw my way through a fresh carrot with a dulled dinner knife, I was able to learn the art of rocking a chef knife, and best of all, it could be sharpened!

A friend explained that the basic difference was the dinner knife had been stamped out of a single piece of sheet steel and the chef knife was hammered by a forge. He said there was another process, rare, refined and highly desirable, where metal is folded to make it more durable. Even more incredible was a process of folding two different grades of steel. This process of laminating different grades of steel was also known as Damascus and widely used in the Near East from the 3rd to the 17th century. The extraordinary blades also became the most sought after swords of ancient Japan, used by fiercest of Samurai. In the early Twentieth Century, this technology was used to produce some of the finest kitchen cutlery in the world. In 2002, Kai Group, headquartered in Tokyo with a factory located in Seki City (Japan) introduced Shun Cutlery to the world.

If eating is to be a pleasure for the stomach, it must first be a feast for the eyes. The same can be said for the tools used in preparing your meal. Every cutting implement we own has a story. There is a fifty year old #1 Chinese cleaver, rugged enough to drive 20p nails, sharp enough to thin cut fresh pasta without tearing. German and American chef knives ranging from six to ten inches, vintage French Sabatier knives, and several others of note from China. The prettiest by far are the Shun Nakiri whose edge is legend. Unlike the brutality of a cleaver, this knife is made for prepping vegetables. An exquisitely sharp blade allows a simple up & down motion for cutting instead of the traditional ‘rock’ used for the chef knives.

At an early age, we taught our daughter to cook. Meals were a time of joy to share the goings on of the day or to plan adventures. After every great meal, there was an equally great mess. This was also a time to learn the importance of washing, drying and sharpening the knives before their next use. My grandparents owned one knife, a relic brought from their old country. Its square wooden handle had worn almost round from generations of use. Every month they would trust a push cart street vendor with this prized possession. With just a few revolutions of a giant stone wheel the keen edge reappeared. I had witnessed magic.

I never mastered sharpening on a stone. Neither flat nor round gave up their secret to me. For years I would rely on a high-end kitchen store to send my knives out to be sharpened and restored. Seven business days seemed an eternity. The wait was worthwhile. As the store grew in popularity, they added cooking classes. The first one was not about cooking, but dedicated to knife sharpening. Finally, a friendly electric machine that could do perfectly what I could not. It came home with me that very day. An electric marvel, this two bay Chef’s Choice sharpener brought life back to the stained carbon Sabatier that had been a faithful companion for several decades.

Life presents alluring choices and sometimes more interesting chances than ever the imagination could conjure. As my knife collection increased so did the understanding of metals, hardness, handle shape and comfort. A more complex issue was how the shape of the blade affected the taste of the food I prepared. Thinly sliced vegetables gave more area to season. Meat cut with a serrated blade had a different texture than that finely sliced.

Several questions still vexed: Was a folded compound steel blade a better choice as a cutting tool? And did the sharpener give agency to a superior edge? The only to answer these questions was to do a head to head comparison using a Chef’s Choice 120 and a Work Sharp Culinary E5.

I chose two Permier Shun Nakiri 5.5” right out of the box and sharpened both according to the manufacturers recommendations. The test was to slice tomatoes, basil, garlic, Pumpernickel and French bread.

Both knives performed flawlessly on the garlic and bread. They were the easiest to cut as they had a bit of ‘give’ and a ragged edge would scarce be noticed. The tomato gave no resistance to the knife sharpened with the E5 and just a slight hesitation with the one sharpened with the Chef’s Choice. The basil, however would define the keenest edge. Anything less than a perfect dissection would tear the delicate leaves.

A small black dot was placed on the handle of one knife, the other left blank. These became Knife ONE and Knife ZERO respectively. Rather than rely solely on a perception of how each felt while slicing, I examined both blades under a microscope immediately after use. Both showed marks of recent sharpening as expected. However, the Chef’s Choice sharpened knife also showed the characteristic ‘rope’ or ‘burr’ that was expected of a blade sharpened only in one direction. Even after sharpening and use, this defect remained! There was an unmistakable difference between the feel of both blades as they cut. The ‘burr’, gave noticeable resistance when drawn across the delicate basil.

Our kitchen is tiny, keeping the necessary tools and appliances within reach is often a difficult task. The Work Sharp Culinary E5 occupies space that is almost as sacred as it is scarce. While not a gourmet chef, I love to cook. I do not gallop, I am not frugal nor am I French. Even with those shortcomings guests never fail to make quick work of the meals prepared and served at our house. I keep looking for a downside to owning an E5 and may have found it. Friends have asked me to sharpen their knives…and that brings a smile to my face!

Learn More About Work Sharp Culinary Kitchen Knife Sharpeners

Follow us on Facebook for the Latest Great Recipes and Kitchen Hacks